SWEDTURN X

Production machines that measure up.

Our SWEDTURN machines are developed with a deep understanding of the fundamentals of machining and metal removal with a clear vision of what is required for efficient production today.

By combining decades of experience with the latest technology, we deliver reliable, high-performance solutions for complex and heavy machining.

From robust construction to smart chip management, every detail is designed to ensure long-term precision, efficiency and adaptability in a rapidly changing industry.

A reliable solution for advanced machining

SwedTurn X was developed in close collaboration with our long-standing customers in the defense and automotive industries. The machine retains core features that have been difficult to find elsewhere – including our solid machine bed, outstanding reliability in continuous production and exceptional repeatability for high-volume production.

MACHINE PROTECTION - NEW DESIGN

A new, simplified design of the machine guard inspired by Scandinavian design. A development with a focus on easy maintenance, operator accessibility and loading of workpieces both from above and from the side, with a robot or overhead crane.

IMPLEMENTATION IN PRODUCTION CELL

A new improved concept for implementation in production cells developed together with ABB Robotics and available with several different options depending on your needs.

ERGONOMIC WORKING POSITION

The new entry and doors that open from top to bottom allow the operator to easily enter the machine, resulting in improved operator accessibility and easy loading of workpieces from both the top and side.

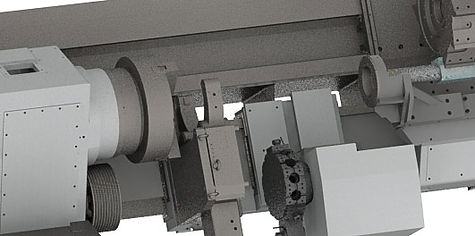

THE FOUNDATION OF PRECISION

Our proven, stable, cast machine bed is the foundation for heavy precision machining. With the new improved SwedTurn concept, it is a production machine for the future.

DIGITAL TWIN

Siemens Sinumerik ONE is the digital twin that makes it possible to optimize machining. The digital machine twin supports the operator – even if the machine tool is manually operated.

CUSTOMIZATIONS

We have a library of hundreds of different solutions from different projects. If what you are looking for has not been done before, our designers will develop a solution that is optimal for your needs.

Machine program

SwedTurn is a reliable, modular turning system, built on our base machines. The machines are designed and developed to meet the high demands of Swedish industry regarding efficiency, high precision and stability. All products are delivered operator-friendly, for easy changeover, workpiece accessibility and with consideration for smooth service.

Machine builder since 1856

1856

Köpings Mekaniska Verkstad was founded by Otto Hallström for the manufacture & repair of agricultural machinery which was soon expanded to include machinery & mechanical products that Sweden was in need of for industrialization. The brand name was "KÖPING".

1920

The company is acquired by AB Volvo. At the Köping mechanical workshop, Volvo produced gearboxes and rear axles for passenger cars and trucks, as well as the machines that Volvo needed in its own production.

1960

In the 1960s, Volvo decided to cease its own production of machine tools. The machine tool manufacturing was sold to the Swedish state and became part of the conglomerate Statsföretager, which was strongly linked to Sweden's then-current defense industry.

1968

The company introduces its first numerically controlled lathe and begins the journey towards a high-tech company.

1972

SMT launches its first CNC control, i.e. a control system where block preparation, logic and interpolators are implemented in software running on a microprocessor.

2004

After several different owners and mergers, SMT's Swedturn division (Lathes) was sold to the owners of STOREBRO Machine Tools, who are also machine tool manufacturers.

2010

SMT Machine flyttar från Västerås till Köping i närheten av där företaget från början startades.

2020

SMT Machine is gathered together with STOREBRO Machine Tools & SMT Milling Machines under the umbrella SMT Swedish Machine Tool Company AB

2021-22

A strategic move to Främmestad, where the new machine factory and head office are located.

2023

EMO: Launch of SwedTurn X - our new, improved turning concept for today's and future production.