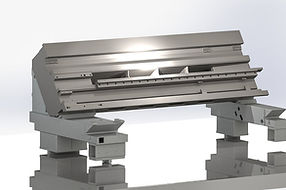

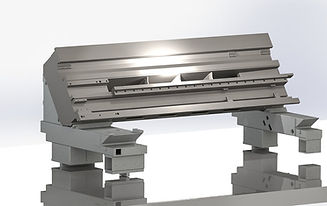

SWEDTURN X ST 500

A reliable turning system with capacity; Ø500 up to length 4000mm

ST 500 X

Robust construction for heavy-duty processing

The ST500 is built to handle demanding production with high stability and precision.

High precision and repeatability

The machine delivers consistently accurate results - well suited for non-stop production.

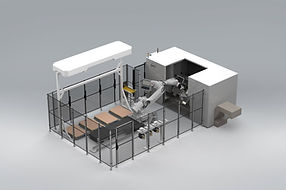

Flexible configuration

The ST500 can be customized with different spindle options, tooling systems and automation – to suit your specific needs.

Long service life and low operating costs

Well-thought-out design and high-quality components result in a machine that lasts a long time and requires minimal maintenance.

Swedish-made machine tool

Developed and manufactured in Sweden – with access to local service, technical support and spare parts.

Technical data

Svarvkapacitet

Avstånd spindel-Dubbdocka 2-axlig (4-axlig*)...............................mm 1390/1890/2590/4090

.............................................................................................................mm *(1120/1620/2620)

Sving diameter max..........................................................................mm 650

Svarvbar diameter max....................................................................mm 570

Max detaljlängd vilken kan bli bearbetad 2-axlig..........................mm 1200/1650/2350/3850

(4-axlig*).............................................................................................mm (900/1400/2400)

Spindeldocka

Effekt huvudmotor AC 100% (60%) (*Option)................................40/50 (60/71*)

Max vridmoment huvudmotor 100% (60%)(*Option)...................4000/5000 (6000/6900*)

Varvtalssområde med fullt vrid (*Option)......................................150-2000 (100-1500*)

Spindeldiameter främre lager..........................................................mm 170 (260*)

Chuck diameter..................................................................................mm 500 (*)

Verktygsbärare - Revolver (Direct drive/ ATC som option)

Verktygshållare VDI / DIN 69880 .....................................................12xVDI50 (VDI60*)

Antal drivna stationer* .....................................................................12

Verktygsdrift effekt/varvtal ...............................................................10,6/2500 (12,7/2250*)

Slidrörelser (bakre revolver)X/Z/Y* ..................................................mm 380/1400/110

Snabbtransport X/Z/Y* ......................................................................m/min 15/15/10*

Slidrörelse (bakre revolver)

X/Z/Y* maskinlängd 1300 ..................................................................mm 380/1295/130

X/Z/Y* maskinlängd 1800 ..................................................................mm 380/1795/130

X/Z/Y* maskinlängd 2800 ..................................................................mm 380/2795/130

X/Z/Y* maskinlängd 4000 ..................................................................mm 380/3995/130

Snabbtransport X/Z/Y* .......................................................................m/min 15/15/10*

Slidrörelse (främre revolver) OPTION

X/Z maskinlängd 1300 ........................................................................mm 260/900

X/Z maskinlängd 1800 ........................................................................mm 260/1400

X/Z maskinlängd 2800 ........................................................................mm 260/2400

Snabbtransport X2/Z2 ........................................................................m/min 7,5/15

Pinoldocka

Pinolrörelse, hydraulisk ......................................................................mm 150

Max pinoltryck .....................................................................................daN 3000

Maskinvikt ............................................................................................kg 9000/11000/13000/15000

Styrsystem ..........................................................SIEMENS Sinumerik 840D (Shopturn*)

Features

Control system

With Siemens Sinumerik ONE, a digital twin is enabled that optimizes the machine's production processes. The digital machine twin can support the operator – even during manual operation.

Available with Fanuc or Fagor.

Applications

One of our great strengths is our ability to adapt both machines and functions to your specific requirements. We have an extensive library of hundreds of customized solutions. At SMT, the customer's needs are always at the center. We offer flexible and customized machine solutions that meet the high demands set in the industry - regardless of whether it concerns lathes, milling machines or complete production systems. We create cost-effective solutions that deliver high precision, maximum operational reliability and long service life = production systems that can grow in step with your production.

.jpg)