TURN X MILL

Complete complex parts in one pace.

TURN X MILL

Efficient single-setup machining

Our milling spindle was introduced as a option in the early 2000s, leading into developing our TURNXMILL series to meet the growing demand for efficient, single-setup machining.

Based on the proven SwedTurn legacy, its modular design combines flexibility with the high precision required in advanced manufacturing.

The TURNXMILL maintains core features our customers trust: a solid, thermally stable bed, reliable continuous operation, and exceptional repeatability in high-volume production.

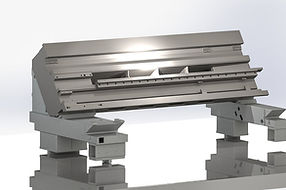

The multifunctional TXM500 and TXM800 turning-boring-milling centers enable complete single-setup machining of complex components, with swing diameters up to 750 mm and lengths up to 2350 mm. These advanced machines combine turning and milling functions in one solution, supporting a wide range of operations—including threading, drilling, boring, milling, gear hobbing, grinding, and in-process measuring.

A 18/27/30 kW milling spindle with integrated motor and top-mounted tool magazine ensures fast tool changes and space efficiency. The sub-spindle, available with 30/39 kW or 44/49 kW, can be equipped with custom chuck systems.

With the ability to handle workpieces up to Ø700x3500 / Ø800x3400 mm, plus C-axis operation and a front tool turret, the TXM series delivers precise, heavy-duty machining in a single setup. Standard control is Siemens Sinumerik One with Fanuc and Fagor available as an option.

Features

Your choice of control system, tailored to your preferences – from simulation to reality.

As standard Siemens Sinumerik One

> ”Top speed + top surface” deliver high quality contours at faster speeds on complex surfaces. The SIMATIC S7-1500F PLC speeds up cycle times and delivers faster hardware responses, Cutting tool changes and other PLC-related tasks is executed with greater efficiency.

> Supports turning, milling, multitasking, and other manufacturing processes in one system.

> High resolution multi-touch panels, powerride override controls for faster and better run-in. mobile control via the portable HT 10 terminal.

> OPC UA 3.0 enables fast and secure data exchange in industrial environments.

Available with > Fanuc 31ii-B5 Plus > FAGOR CNC 8065 ELITE M

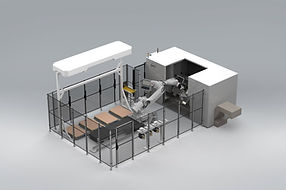

MACHINING POSSIBILITIES Technology diversity